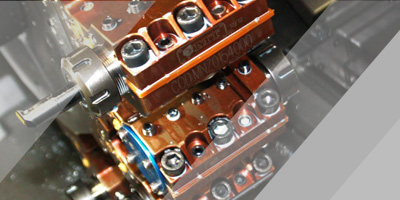

We specialise in manufacturing in high speed steel, tungsten carbide, poly crystalline diamond (PCD) and the latest Powder metallurgy steels - to customer’s specific requirements.

Special short run batches are regularly undertaken as well as large number batches.

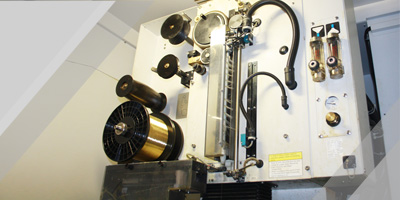

Over the years Pen Cutting Tools has established both in the United Kingdom and abroad, an enviable reputation for its product quality and service, particularly in the Bearing, Mould and Die and General Engineering Industries. Pen Cutting Tools has also installed ISO 9001:2015 Quality Assurance and management system, which is checked and updated by Lloyds of London. We have equipped all areas of our production with both the machinery and skill levels to produce high tolerance work to customer specifications in a wide range of materials. A glance at our production facility shows the expertise on offer.

We have developed alongside the bearing industry a capability to form shapes on carbide / cermet and ceramic inserts to close limits for turning applications and, as with all our products, a range of coatings are available. Pen is a full service company that can give advice on tool design to help increase tool life and can also aid designers when it comes to what is possible to manufacture.